Think of our planet’s grand challenges: Managing climate change. Reducing energy use. Sustaining food production. Improving global health. Many of these efforts involve overlapping problems—and the potential for interlinked solutions. It’s no wonder the United Nations names “Partnerships” as its 17th Sustainable Development Goal.

In this 10th edition of the “Top 10 Emerging Technologies,” created by Scientific American and the World Economic Forum, that interlinking is front and center. With the acceleration of government and industry commitments for decarbonization, we will see an array of novel approaches in low-emission transportation, residential and commercial infrastructure, and industrial processes. Two such technologies—the production of “green” ammonia and engineered crops that make their own fertilizer—will improve agricultural sustainability. In remote areas, 3-D printing with local soils will erect stronger houses with less energy.

Because health is on everyone’s mind, this year’s Top 10 salutes the rise of breath sensors that can detect COVID-19 and other diseases, as well as wireless biomarker monitors that make it easier to diagnose and manage chronic illnesses. New results from the field of genomics could allow us to engineer longer “healthspans,” and on-demand drug manufacturing will result in tailored medicines while helping to solve today’s supply challenges with large-scale production.

To keep track of it all, the number of devices that make up the Internet of Things is rapidly growing. They will become more globally connected through the use of orbiting nanosatellites and be powered by energy harvested from wireless signals. The future has never looked so interconnected.

—Mariette DiChristina

and Bernard S. Meyerson

Climate change: Decarbonization Rises

Sweeping commitments to address climate change will birth new technologies

By Bernard S. Meyerson

More than a century after the first scientist argued that carbon dioxide could trap heat in the atmosphere and decades after “climate change” entered the vernacular, countries and industries have been making new commitments to cut their carbon footprints. In 2021 the U.S., the second-largest source of national carbon emissions, committed to halve its output relative to 2005 levels by 2030. The U.K. announced its own aggressive goal of a 68 percent reduction compared with 1990 levels by that date. The European Union Parliament recently passed a law requiring carbon-emissions reductions by at least 55 percent by 2030 compared with 1990 levels. Although industries such as oil and aviation are more resistant to change, the rate at which companies are joining the Science-Based Targets initiative, which helps them reduce their emissions to stay in line with the Paris agreement, has doubled since 2015. General Motors, Volkswagen and other major auto manufacturers have set ambitious targets for decarbonization in the past year.

This acceleration of commitments—along with its associated challenges—is a clear indicator of decarbonization’s emergence worldwide. It will force a diverse suite of technologies to “emerge”—that is, to demonstrate the ability to operate at scale in the next three to five years. To make this a reality, solutions that have already been identified must mature and scale at greater speed. Existing technology gaps will require sustained innovation. We expect several broad areas to see significant focus and growth.

Today 2 percent or less of global private and commercial roadway transportation fleets produce zero emissions, despite Tesla’s highly visible initial success in driving consumer interest. Meanwhile bulk shipping, both rail and seaborne, has devised low-carbon solutions. Yet many of them, such as the Coradia iLint, a passenger train powered by hydrogen fuel cells and manufactured by Alstom, have yet to be applied at scale. The barriers are not just technological but also political, given that such transformational programs require significant capital investment.

In the U.S., an estimated 13 percent of total carbon emissions come from fuel used for heating and cooking in residential and commercial buildings. Reducing that number in America and elsewhere will demand net-zero-emission HVAC (heating, ventilation and air-conditioning), and passive solar environmental systems must become commonplace. It will also be important to switch to natural and novel building materials such as renewable timbers and low-carbon-footprint cement.

As renewable energy sources become abundant, we will need to employ them to decarbonize pervasive sources of greenhouse gases. One example is “green” hydrogen. When produced without using carbon-based fuels, hydrogen can become a nonpolluting fuel while also serving the chemical industry as a basic ingredient with no carbon footprint. Similarly, if data centers, which often require megawatts of electricity, are co-located with the same renewable energy sources, their carbon footprint is dramatically reduced.

Meeting the power–generation goals set by nations and industries requires a radical expansion of photovoltaic, wind, hydroelectric, tidal, nuclear and other zero-emission tech. Some critical hurdles remain: Reliable, efficient and affordable energy storage at the industrial scale is nascent. Carbon-free, fission-based nuclear energy (including disposal of its waste products) that is both safe and affordable is also still aspirational. To lessen the pollution from existing fossil-fuel power generation, we will also need to bring on far more technologies that capture, reuse and sequester carbon.

In the agriculture sector, protein substitutes such as the Impossible Burger and Beyond Meat will need to take over a much greater share of the market to mitigate the massive levels of carbon and methane produced in raising livestock. Data from sensors connected via the Internet of Things will increasingly enable intelligent land and crop management as well as fertilizer and water use, aiding in further carbon reductions.

In addition to the myriad technological challenges to rapid decarbonization, nations must develop global governance methods to ensure energy equality. Emergent economies cannot face identical carbon-reduction targets that would stifle development. Nations will also need to thoughtfully allocate land to expand infrastructure for renewables. And to ensure compliance with global accords, governments will need global environmental monitoring infrastructure, similar to the protocols of the International Atomic Energy Agency.

Agriculture: Crops That self-Fertilize

Root-grown instead of sown

By Wilfried Weber and Carlo Ratti

Providing food for the world’s growing population relies heavily on the use of nitrogen-containing industrial fertilizers. Some 110 million tons of nitrogen are required to sustain global crop production annually, according to the U.N.’s Food and Agriculture Organization. Nitrogen fertilizer is typically produced by converting nitrogen from the air into ammonia, a form of nitrogen that can be utilized by plants. This conversion sustains approximately 50 percent of global food production and accounts for an estimated 1 percent of the world’s primary energy needs, but it is also an energy-intensive process: it accounts for 1 to 2 percent of global carbon dioxide emissions. Furthermore, industrial fertilizers are too expensive for smallholder farmers in many countries, leading to strongly decreased yields and increased pressure on natural lands.

To develop a solution, researchers are taking cues from nature’s own approach to making nitrogen fertilizer. Whereas staple food crops such as corn and other cereals rely on inorganic nitrogen from the soil, legume plants such as soy and beans have maintained a clever way to produce their own. The roots of legumes interact with soil bacteria, leading to bacterial colonization of the root and formation of symbiotic organs called nodules. Within these structures, the plant provides sugars to sustain the bacteria and profits from the bacteria’s ability to fix nitrogen—that is, to convert atmospheric nitrogen into ammonia. Thus, through an evolutionarily ancient symbiosis with soil bacteria, legumes are independent of modern nitrogen fertilizers.

Researchers have shown that the formation of the nodules—the natural fertilizer factories—involves intimate molecular communication between soil bacteria and legume roots. This knowledge has inspired exciting new approaches to engineering nitrogen fixation into nonlegume plants. For example, scientists are coaxing the roots of cereals to engage in symbiotic interaction with nitrogen-fixing bacteria. The researchers emulate the molecular communication between legumes and bacteria and steer the process by which the bacteria can colonize plant roots. In an alternative approach, soil bacteria that naturally colonize the roots of cereals but cannot fix nitrogen are taught to produce nitrogenase, the key enzyme that converts nitrogen from the air into plant-compatible ammonia.

With governments and private foundations recently providing strong support for research and development in the area of engineering nitrogen fixation, crops that harness the power of natural symbiosis might soon become a key element of a more sustainable food production.

Biochemistry: Breath Sensors Diagnose Diseases

Puffing is far faster than drawing blood

By Rona Chandrawati and Daniel E. Hurtado

When police officers suspect a motorist is intoxicated, they can use a Breathalyzer: a handheld device that measures the level of alcohol in the blood. Can the same be done for disease diagnosis?

The short answer is yes. Human breath contains more than 800 compounds, and recent discoveries have shown a strong correlation between certain concentrations of compounds and different disease states. For example, breath with a significantly elevated acetone concentration is a strong indication of diabetes mellitus; a higher concentration of exhaled nitric oxide is correlated with inflamed cells and therefore can be used as a biomarker for respiratory diseases; greater amounts of aldehydes are closely related to lung cancer.

When a person puffs into a sampler, that breath is fed into a sensor that generally makes detections based on changes in the electrical resistance of metal oxide semiconductors. Within minutes, a software analysis by an external computer generates a profile of the compounds present.

Beyond delivering results far faster than a blood draw, breath sensors could streamline medical diagnostics by providing a noninvasive way to collect critical health data. In low-income countries with limited medical resources, their ease of use, portability and cost-effectiveness provide new opportunities for health care. These devices could also help mitigate community spread of a virus in a manner similar to how temperature checks screen individuals before they enter shared indoor spaces such as supermarkets or restaurants.

In March 2020 Hossam Haick and his co-workers at Technion-Israel Institute of Technology concluded an exploratory clinical study in Wuhan, China, for COVID detection in exhaled breath. The sensors achieved a remarkable 95 percent accuracy and 100 percent sensitivity in differentiating people who were positive or negative for the disease. In 2021 the U.S. Department of Health and Human Services provided $3.8 million to repurpose NASA’s E-Nose—a monitor that uses nanosensor array technologies to autonomously scan the air on the International Space Station for potentially dangerous chemicals—to detect COVID.

Critical challenges need to be met before breath-sensor technology becomes widespread. First, detection accuracy must be improved for some diseases, particularly for tuberculosis and cancer. Second, various compounds in a breath sample can confound test results, creating false positives. The algorithms that analyze sensor data will also need to be improved to reach greater accuracy. Finally, bigger investments in clinical trials are needed to help validate this technology in large populations.

Engineering: On-Demand Drug Manufacturing

Making pharmaceuticals where and when they are needed

By Elizabeth O’Day and Mine Orlu

What if the next time you went to your local pharmacy, rather than the pharmacist looking through aisles of premade drugs to fill your prescription, he or she made it to the exact dose and formulation tailored for you? Recent advances in microfluidics and on-demand drug manufacturing are poised to make this idea a reality.

Traditionally drug products are made in large batches through a multistep process with different parts dispersed among many locations across the globe. Hundreds of tons of material support such mass production, creating challenges in ensuring the consistency required for both quality and reliable supply. It can take several months to complete drugs and deliver them to stores.

In contrast, on-demand drug manufacturing, also known as continuous-flow pharmaceutical manufacturing, makes drugs all in one go. It works by flowing ingredients via tubes into a series of small reaction chambers. Producing drugs as needed at a single site means that drugs can be made in remote locations or in field hospitals. It also means fewer resources are needed to store and transport drugs and that doses can be tailored to individual patients.

In 2016 researchers at the Massachusetts Institute of Technology working with DARPA (Defense Advanced Research Projects Agency) first demonstrated it was possible to make on-demand drugs. They created a refrigerator-size machine that used continuous flow to make four common drugs: diphenhydramine hydrochloride, which is used to relieve symptoms of allergy; diazepam, which is used to treat anxiety and muscle spasms; the antidepressant fluoxetine hydrochloride; and the local anesthetic lidocaine hydrochloride. They made 1,000 doses of each drug within 24 hours.

On Demand Pharmaceuticals is now commercializing the original M.I.T. work, with several platforms available or in development, including American Made Precursors on Demand (AMPoD), which enables full drug-product manufacturing from precursor to final formulation; Bio-Mod, which enables the manufacture of biologics; and IV Medicines on Demand, which produces sterile injectables. A number of pharma manufacturers, among them Eli Lilly, Johnson & Johnson, Novartis, Pfizer and Vertex Pharmaceuticals, are also making use of continuous-manufacturing technology at least for parts of their manufacturing processes.

Currently portable machines for on-demand drug manufacturing cost millions of dollars, preventing widespread rollout. New methods of quality assurance and quality control also will be needed to regulate both the personalization of formulas and single-person drug batches. As cost goes down and regulatory frameworks evolve, on-demand manufacturing may revolutionize where, when and how drugs are made.

Computing: Energy from Wireless Signals

5G will help power the Internet of Things

By Joseph Costantine

The wireless devices that make up the Internet of Things (IoT) constitute the backbone of an ever more networked world. They are deployed as gadgets in homes, as wearable devices for biomedical uses, and as sensors in hazardous and hard-to-reach areas. As the IoT grows, it is enabling agricultural practices that use less water and pesticide; more energy-efficient smart grids; sensors that monitor flaws that can weaken bridges or concrete infrastructure; and early-warning sensors for disasters such as mudslides and earthquakes.

With an estimated 40 billion IoT devices coming online by 2025, providing convenient, on-demand power to those devices is a fast-growing challenge. One solution that is already in the works leverages the wireless signals emanating from Wi-Fi routers and access points. The emerging fifth generation of cellular technology, or 5G, will elevate wireless-energy harvesting to a new level.

With 5G, the Federal Communications Commission is allowing cell signals to move into the higher (but still safe for humans) millimeter range of the electromagnetic spectrum for the first time. Along with higher information rates, 5G wireless signals transmit a greater amount of radiated energy than 4G. This capability points to a future where many low-power wireless devices never need to plug in to charge.

How can devices grab power from wireless signals? Wi-Fi and 5G are electromagnetic waves that propagate at frequencies within the broad spectrum between FM radio, microwaves and millimeter waves. The first step of the process involves a receiving antenna that captures energy carried with the wireless signal. The antenna routes that energy into an electronic rectifier circuit, which in turn uses semiconductors to convert it into a direct-current (DC) voltage that can charge or power a device. This combination of antenna and rectifier (or converter) is called a rectenna. A power-management circuit follows the rectenna, amplifying the voltage while itself consuming negligible power.

Many start-up companies are now offering wireless charging products that currently rely on dedicated wireless transmitters; research suggests it is likely, however, that such devices will be able to harvest Wi-Fi and 5G signals in the near future. Just as cell phones free us from landlines and have transformed our communication ability, this emerging technology will free us even further.

Genomics: Engineering Better Aging

A focus on increasing “healthspan,” not just lifespan

By Wilfried Weber and P. Murali Doraiswamy

According to the World Health Organization, between 2015 and 2050 the proportion of the global population older than 60 will nearly double from 12 to 22 percent, posing enormous challenges to health and social systems. Aging is related to chronic diseases such as dementia, cancer, type 2 diabetes and atherosclerosis. The desire to reverse aging or to find a “fountain of youth” is likely as old as humankind. We are beginning to understand the molecular mechanisms of aging that could help us lead lives that are not just longer but healthier.

Through the advent and refinement of so-called omics technologies (which simultaneously quantify, for example, the activity of all genes or the concentration of all proteins and metabolites in a cell), combined with insights from epigenetics, those key mechanisms are becoming clearer. One exciting example involves combinations of specific epigenetic marks (modifications that change gene activity because of behavior and environment) or metabolic compounds that can serve as identifiers of an organism’s biological age.

Such marks also are strong predictors of diseases in the elderly and the accompanying risk of death. Advances in sequencing the genetic information of single cells in an organism have demonstrated that the number of mutations increases during aging; the body’s repair of such mutations may leave aging-related traces on the DNA—another type of marker. DNA damage is also associated with driving cells into senescence (meaning they can no longer reproduce) or exhausting the stem cells that are key for cell and tissue renewal.

This recent and continuously growing understanding of aging mechanisms is enabling the development of targeted therapies. For example, one recent initial clinical study suggested that a one-year-long administration of a pharmaceutical cocktail, including human growth hormone, could turn back the “biological clock” 1.5 years. Similarly, researchers successfully demonstrated in a rodent model that gene therapy targeting three longevity-linked genes could improve or reverse four common age-related conditions. Scientists have also identified proteins in the blood of young humans that, when infused into older mice, improved markers of age-related brain dysfunction. The result suggests therapeutic potential to reverse human age-related cognitive decline.

Inspired by new insights into the aging process at the molecular level and encouraged by the first promising results from clinical trials, more than 100 companies are actively developing pharmaceutical or gene-engineering approaches to analyze and engineer “healthspan” and lifespan. Most of these companies are at preclinical stages or early clinical trials. This R&D, backed by investors’ high expectations, fuels hopes for healthier elderly years.

Chemistry: Green Ammonia

Reducing the CO2 footprint of fertilizer production

By Javier García Martínez and Sarah E. Fawcett

The Haber-Bosch process—arguably one of the most important inventions of the 20th century that many people have never heard of—enables synthesis of ammonia on an industrial scale. This ammonia is used to produce the fertilizers that fuel 50 percent of global food production, making it a key to food security around the world. Ammonia synthesis, however, is an energy-intensive chemical process that requires a catalyst to fix nitrogen with hydrogen.

Unlike nitrogen, which makes up most of the air we breathe, hydrogen must be synthetically produced and is currently generated using fossil fuels. Natural gas, coal or oil is exposed to steam at high temperatures to generate hydrogen gas. Problematically, this process yields vast amounts of carbon dioxide, accounting for 1 to 2 percent of total global emissions.

Green hydrogen, produced by splitting water using renewable energy, promises to change that. In addition to eliminating carbon emissions during hydrogen production, the process has a significantly purer end result. It is free of chemicals that are incorporated when fossil fuels are used, such as compounds containing sulfur and arsenic that can “poison” the catalyst, thereby reducing reaction efficiency.

Cleaner hydrogen also means that superior catalysts can be developed because they no longer need to tolerate the poisonous chemicals from fossil fuels. In fact, companies such as Denmark’s Haldor Topsoe have already announced the development of novel catalysts from entirely renewable sources for green ammonia production.

Spanish fertilizer producer Fertiberia is partnering with energy company Iberdrola to vastly expand green ammonia plans, from a 20-megawatt pilot plant that will be operational in 2021 to a full 800 MW of solar-driven electrolytic hydrogen production by 2027. The investment, estimated at 1.8 billion euros, is expected to generate 4,000 jobs and save 400,000 tons of CO2 a year, equivalent to the emissions of about 60,000 cars.

A major obstacle is the current high cost of green hydrogen. To help solve that problem, 30 European energy players have launched HyDeal Ambition, a project aiming to deliver green hydrogen at 1.5 euros per kilogram before 2030 through innovations in the production, storage and transport of hydrogen. If successful, the effort could unleash a whole range of new applications for green ammonia, including its ability to be decomposed back into hydrogen—enabling a virtuous green hydrogen-ammonia circle.

Bioinformatics: Biomarker Devices Go Wireless

Continuous, noninvasive monitoring of chronic diseases

By Joseph Costantine

Nobody likes needles. But monitoring chronic diseases such as diabetes and cancer requires frequent blood work to identify and track certain biological markers, or biomarkers. Now more than 100 companies are developing wireless, portable and wearable sensors that will soon enable continuous monitoring of this vital information.

Monitors use a variety of approaches to detect biomarkers in sweat, tears, urine or blood. Some use light or low-power electromagnetic radiation (similar to cell phones or smart watches), combined with antennas and electronics, to peer into tissue. Others involve wearable, flexible electronic sensors atop skin. To detect a given biomarker, monitors seek a change in current, voltage or electrochemical concentration.

Diabetes is a top target for this technology, with 578 million people globally expected to be diagnosed with the disease by 2030. To meet the rising need for checking glucose levels, one portable device promises noninvasive monitoring using wireless electromagnetic fields at millimeter waves and near-infrared sensing; the voltage variation in a patient’s finger can be correlated to glucose level. In another approach, wearable electronics embedded in clothing detect glucose levels in the bloodstream with electromagnetic waves within the microwave range. In a third effort, tattoo-based circuitry evaluates glucose in sweat by employing electrodes to produce tiny amounts drawn from the interstitial fluids that naturally leak out of capillaries. Similar to glucose detectors, tattoolike circuits could sample sweat for changes in lactate, an application that is drawing investment from the athletics industry.

The wireless transmission systems can be paired with various types of sensors, including those made with densely aligned carbon nanotubes or ones that drive magnetic nanoparticles into tiny microfluidic channels to detect biomarkers through a change in voltage or current. Such technologies open the door for an “electronic tongue” that is able to distinguish various liquid samples.

Tears can be surprisingly revealing as well. Electronic, transparent contact lenses can wirelessly pick up cancer biomarkers or glucose levels for diabetes monitoring. Saliva biomarkers may indicate physiological and psychological stress or diseases such as HIV, intestinal infections, cancer and COVID. When integrated in a mouth guard that has radio-frequency identification technology, saliva sensors can also monitor oral health, detecting decay or anomalies.

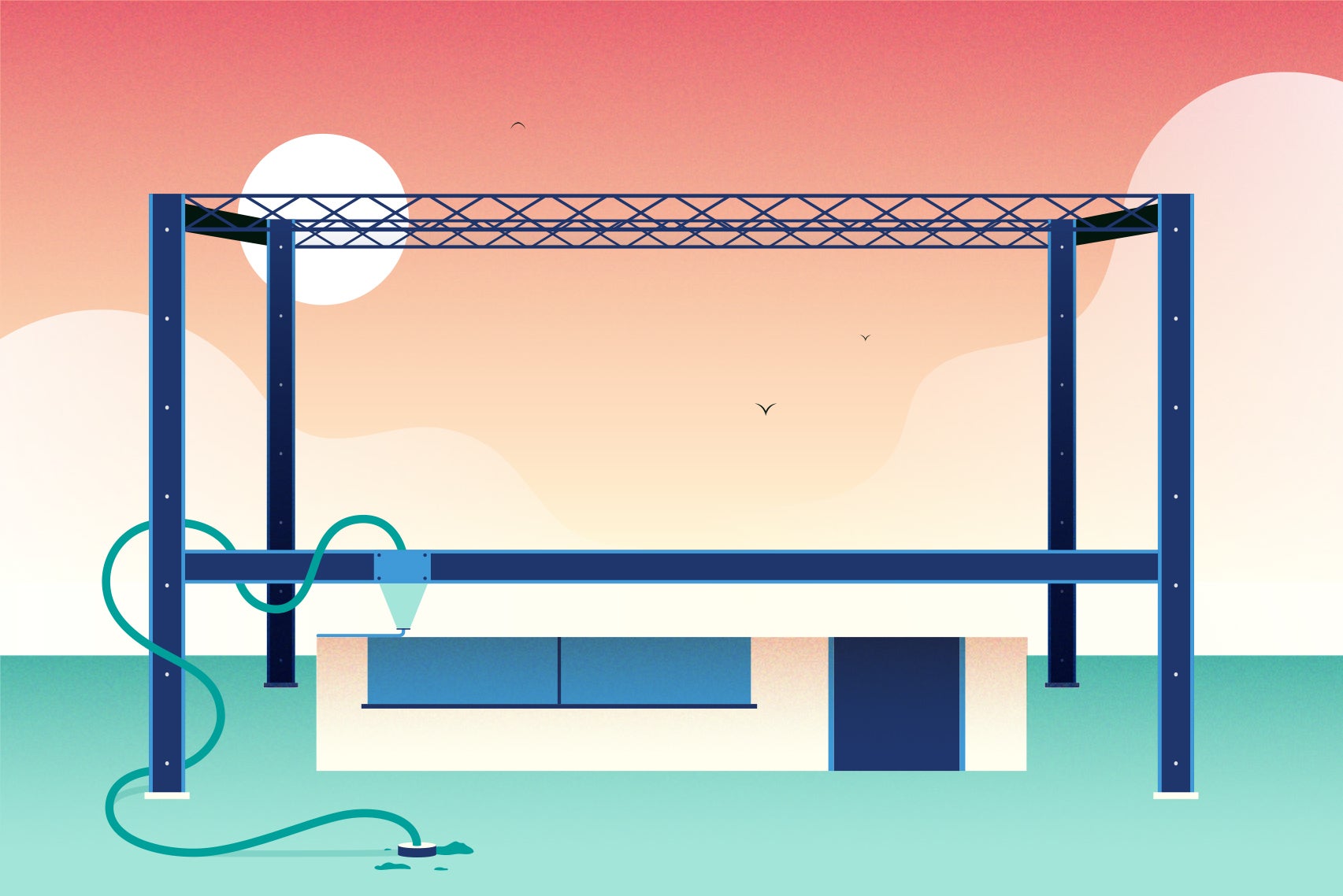

Materials science: Houses Printed with Local Materials

Concrete is swapped for soil

By Bernard S. Meyerson and Carlo Ratti

Technologies such as childhood vaccines or LASIK eye surgery tend to dramatically improve quality of life for many people in the industrial world. But their influence in developing nations has often been far more limited or significantly delayed. Building houses with 3-D printers, however, could help tackle the challenge of inadequate housing for 1.6 billion people worldwide, according to a U.N. estimate.

The concept of 3-D printing houses is not new. Several enterprises have printed homes on Long Island in New York and in Austin, Tex., with promising results. Materials such as concrete and various mixtures of sand, plastics and binders are trucked to the building site and extruded through a massive 3-D printer. As a relatively simple and low-cost construction method, 3-D printing houses seems well suited to mitigating housing struggles in remote, impoverished regions. But the lack of infrastructure for transporting materials has precluded its use.

Recently various firms have taken inspiration from projects intended for Mars, where local materials are the only option available. In the small town of Massa Lombarda, Italy, one prototype designed by Mario Cucinella Architects uses local clay soil for printing housing components, dramatically reducing the complexity, cost and energy use of construction. The soil is mixed with hemp and a liquid binder, then extruded layer by layer by Italian 3-D printing company WASP into the complex shapes and surfaces required of a dwelling. Using native materials eliminates about 95 percent of the mass that would typically need to be transported to a site.

Another approach, demonstrated by WASP in collaboration with designer RiceHouse, is inspired by centuries of experience in creating mud bricks in arid regions. The process involves blending the traditional mixture of mud with a binding filament, which can be naturally occurring fiber. Instead of hand pressing the base material into a mold, the material is pumped through a 3-D printer supplied by WASP to create a house in far less time than required with traditional methods—and with extra strength granted by the rigid geometry of the printed walls. Much of the base material is sourced from the construction site itself.

With the WASP approach, structures that have reached the end of their usable life can simply be broken down to their base materials, and those materials can be reused. This zero-waste, or circular, model goes back thousands of years. Today homes still exist on Mount Erice in Sicily that were constructed of residual materials from 10 centuries of homes that came before them.

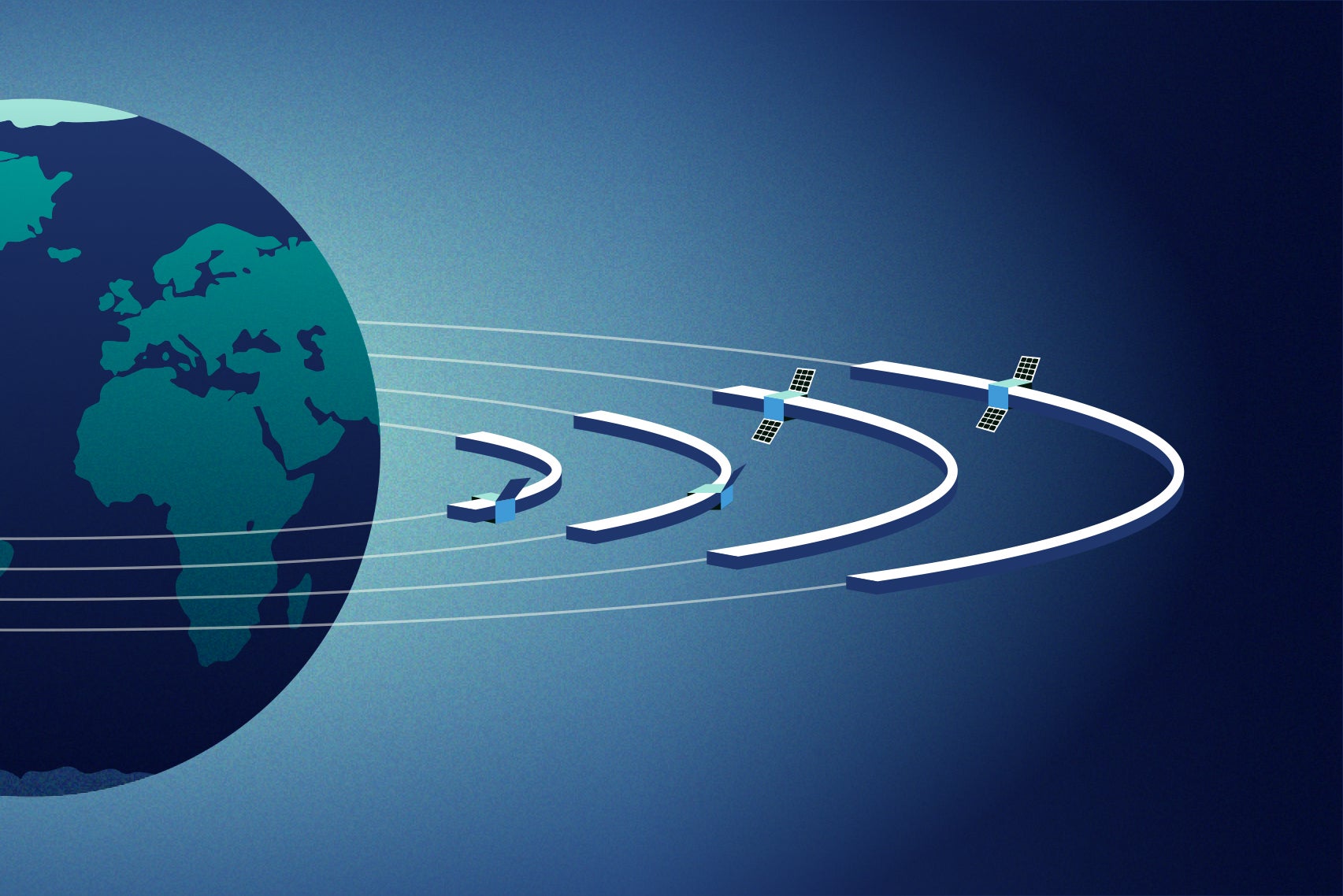

Engineering and computing: Space connects the globe

The Internet of Things goes into orbit

By Rajalakshmi Nandakumar

Today at least 10 billion active devices make up the Internet of Things (IoT), a number that is expected to more than double in the next 10 years. Maximizing the IoT’s benefits in communication and automation requires devices to be spread across the globe, collecting zettabytes of data. The data are assimilated in cloud data centers, using artificial intelligence to identify patterns and anomalies, such as weather patterns and natural disasters. There is a big problem, though: cellular networks span less than half the globe, leaving enormous gaps in connectivity.

A space-based IoT system could patch those gaps, using a network of low-cost, low-weight (less than 10 kilograms) nanosatellites that orbit a few hundred kilometers from Earth. The first nanosatellite launched in 1998; today roughly 2,000 CubeSats serve as orbiting monitors. Companies such as SpaceX Starlink, OneWeb, Amazon and Telesat have used nanosatellites for the goal of providing global Internet coverage.

Soon it will be possible to communicate with these orbiting nanosatellites from small battery-powered IoT devices here on Earth. Data from a device—say, a location reading from a tracking sensor—would be sent to a satellite using low-power, low-cost communication protocols similar to long-range communication and Sigfox, which can decode even weak signals. It would then be transferred to ground stations where the data would be analyzed.

This technology is enabling various data-driven applications in previously unreachable or difficult-to-connect locations. Communications company Iridium, for instance, has a network of 66 low-Earth-orbit satellites that can connect ships to aircraft flying anywhere in the world. Battery-powered sensors from Lacuna Space in the U.K. can connect to their low-Earth-orbiting satellites to track assets such as packages in ships, as well as monitor farm data to enable agriculture that uses water, fertilizer and herbicide more efficiently. Myriota in Adelaide, Australia, uses space-based IoT to track endangered species such as rhinos. And to move data from a satellite to centralized servers in data centers, Microsoft partnered with SpaceX Starlink to launch a space-based cloud computing platform.

Space IoT still faces a multitude of challenges before becoming truly global. For instance, nanosatellites have a relatively short lifetime of about two years and must be supported by expensive ground station infrastructure. To confront the growing problem of orbiting space junk, plans are underway by NASA and others to either automatically deorbit satellites at the end of their functional life or collect them using other spacecraft.

It also will be important to provide secure, reliable, high-bandwidth communication links from satellites to maintain connectivity in different weather conditions and terrains. To do so, companies are working on a different frequency spectrum and developing coding schemes to improve the bandwidth and robustness of the communication systems.

Click here to view the emerging technologies steering group.