Protective gear has come a long way since the days of medieval armor. But engineers still have trouble shielding joints like elbows and knees, which requires material tough enough to prevent injury but flexible enough to allow motion. Toward this end, researchers are imitating an inconspicuous sea animal whose covering strikes a remarkable balance between protection and flexibility.

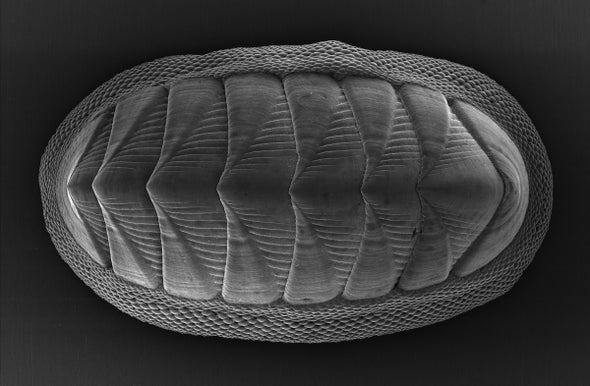

Certain species of marine mollusks called chitons are encircled by girdles of tough tissue capped with overlapping scales of calcium carbonate, the rigid compound that encases many shellfish. Scientists analyzed this ocean armor to learn how it provides freedom of movement without compromising defense, then 3-D-printed protective gear based on its shape. The work appeared last December in Nature Communications.

“We did a systematic study of the material structure, from the nanometer to macroscopic scale,” says study co-author Ling Li, a mechanical engineer at Virginia Polytechnic Institute and State University. He and his colleagues at multiple institutions examined individual chiton scales' chemical composition, crystal structure and mechanical properties, then zoomed out to study how the scales worked together. The type of chiton they studied is about the length of a penny, and its largest scales are only a couple of millimeters wide—so the researchers relied on high-resolution x-rays to image the 3-D geometry of the animals' coverings.

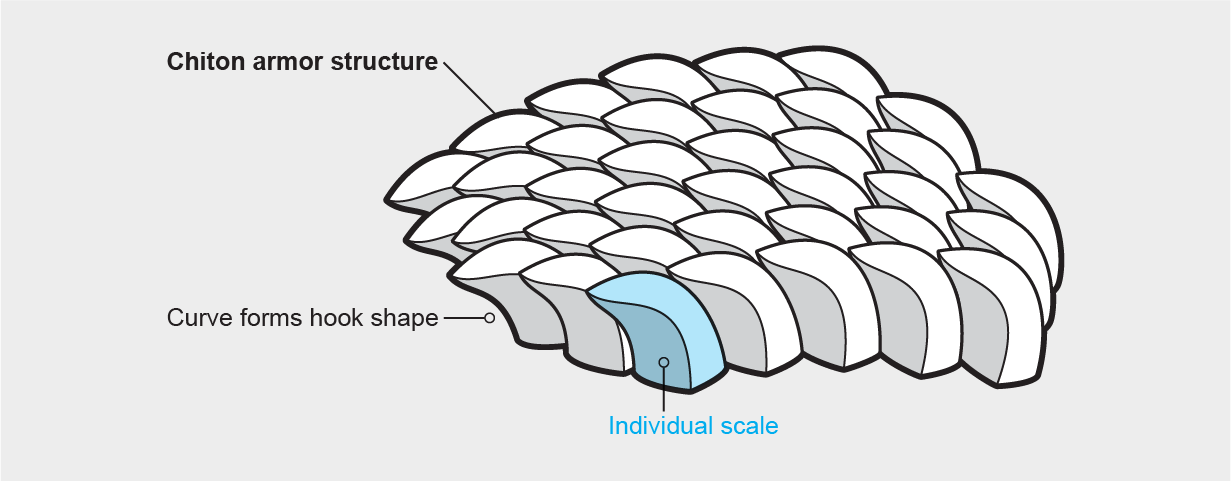

They found the armor gains strength from its interlocking structure. Each scale has a diamond-shaped base that stretches up to a smooth top surface, which curves to hook the plate to its neighbor. When an outside force pushes on one scale, it presses against those next to it, distributing the pressure to protect the organism underneath. Working with architectural designers, the team 3-D-printed analogous scaled armor for humans—including kneepads that protect the wearer from broken glass.

The researchers could then run physical tests on the scales' behavior rather than relying on computer simulations. “This system with a lot of scales that contact each other, that slide along one another—if you try to capture this using traditional computer models, then it becomes a nightmare very fast,” says Francois Barthelat, a mechanical engineer at the University of Colorado Boulder, who was not involved in the study. Printing the structures offers an efficient way to demonstrate the principles involved, he adds.

Li's team tested different scale configurations and investigated how the synthetic armor behaved under stress; he says it could provide protection for athletes or for scientists doing fieldwork. Barthelat notes that it “seems to be pretty efficient at combining flexibility with protection against lacerations.” He suggests the armor could cover any joints, including fingers, and could, for example, help industrial workers: “There's a huge demand for this type of flexible protection.”